Demystifying Honeycomb Yichuang is about to open the 9 th gear era of China car companies

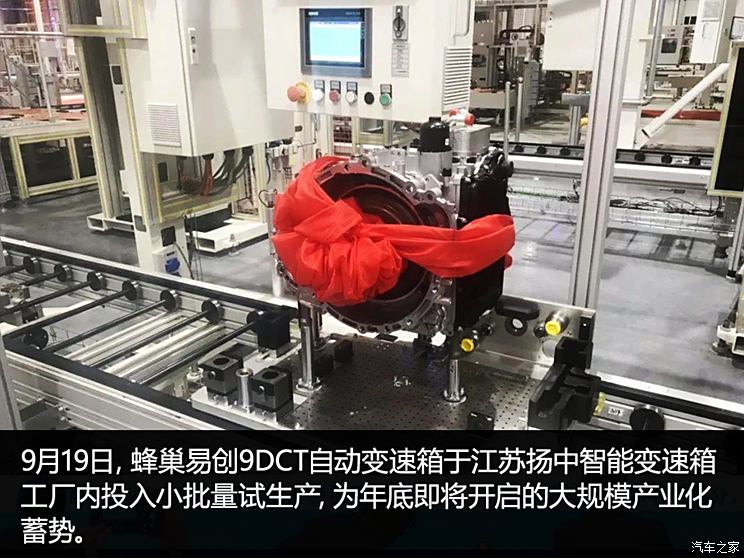

[car home Industry] In two weeks, the automatic transmission industry in China will usher in a major event. Point the coordinates to Yangzhong, Jiangsu, and Hive Yichuang Industrial Park. The first 9DCT automatic gearbox and hybrid powertrain independently developed by local enterprises in China will be officially launched. This indicates that Honeycomb Yichuang "I Era 2.0" will realize industrialization.

As the core of Great Wall Motor’s power system, Honeycomb Yichuang’s "I Era" new generation powertrain 4N20 engine and 9DCT/9HDCT automatic gearbox are both mass-produced in Yangzhong Industrial Park. At the same time, Honeycomb Yichuang’s first 3.0L V6 gasoline engine HY6Z30 and the first 9AT/9HAT are also under simultaneous mass production planning. Recently, Zheng Lipeng, vice president of Honeycomb Yichuang, revealed more key information to car home.

Many people may be unfamiliar with hives. Honeycomb Yichuang, cultivated by Great Wall Motor for many years, is one of the cores of its supply chain system.

In 2018, Great Wall Motor reorganized its parts system, integrating Honeycomb Yichuang (engine, gearbox, electric drive, intelligent steering), Noble Automobile (seat, interior and exterior decoration, rubber, etc.), Jingcheng Engineering (chassis, die casting, equipment, etc.) and Mande Electronics (photoelectric, thermal system, electrification business) successively, participating in market competition and supplying to the outside world. In addition, the power battery industry operates independently with honeycomb energy, and the hydrogen energy industry operates independently with untapped energy and combustion power.

"Honeycomb Easy Creation mainly includes power, transmission, electric drive and intelligent steering business"

At present, Honeycomb Easy Creation is mainly located in Baoding, Xu Shui, Tianjin, Yangzhong, Chongqing and Taizhou. In Yangzhong, the project of honeycomb power system, transmission system and electric drive system will be put into production before the end of this year, and the die-casting project of intelligent steering system and Jingcheng Engineering will be completed by the end of this year.

■ The supply system is completely localized.

Many years ago, when Great Wall Motor no longer relied on foreign procurement of engines, the automatic gearbox became its breakthrough point, and it did not hesitate to point to 7DCT. Since mass production in 2017, with the huge market of Great Wall Motor, Honeycomb Yichuang 7DCT has become a well-known product, and the market share will exceed 2 million units by the end of this year.

Soon, not only the Great Wall, but also many local enterprises in China will enter the 9th gear era.

In July this year, the 4N20 engine in the new generation powertrain of the "I Era" was rolled off the assembly line in Honeycomb Yangzhong, and 9DCT and 9HDCT will be put into production in November, followed by DHT dual-motor hybrid special gearbox. In the future, with the completion of new factories in Taizhou, Jiangsu and Yongchuan, Chongqing, Honeycomb Yichuang will establish a perfect gearbox production system throughout the country.

Why do you want to do the ninth gear? The purpose is to make the engine more efficient. On the one hand, the efficient range of Honeycomb’s innovative first-generation engine will be wider, and on the other hand, the engine will operate in the efficient area as much as possible through the cooperation of the 9-speed automatic gearbox. In addition to the horizontal 9DCT, Honeycomb Yichuang China’s first vertical 9AT and hybrid system will also be unveiled in the future.

Now, the hive can completely not rely on imported parts, the gearbox supply chain is completely localized, and the upstream suppliers are also local and foreign (required to build factories in China). Each component will have different suppliers and can be substituted for each other to maintain the stability of the supply system.

The engine and automatic gearbox are only part of the layout of the honeycomb enterprise.

In terms of electric drive, Honeycomb is supplied by Euler. Since it was put into production in June, the market has more than 10,000 units, and the flat wire motors at the forefront of the market have already been laid out. The Honeycomb Motor Project Team (the predecessor of Honeycomb Electric Drive) made it clear at the beginning of its establishment in 2012 that flat wire is the future development trend, and in 2015, the first Hairpin drive motor was trial-produced. In Yangzhong, the future production capacity of Hairpin motors will be expanded to 500,000 units/year. At present, honeycomb electric drive has developed 45kW-150kW products, while 200kW products are under development.

In terms of steering, Honeycomb turned to independently develop DP-EPS intelligent steering system, which was applied to the latest (|) and Great Wall H9. In the future, Yangzhong will also invest 250,000 sets of annual steering system capacity. Honeycomb turning will also realize foreign matching.

■ Mastering core technologies and opening up cooperation.

Undeniably, the supply system of Great Wall Motor has realized "internal circulation" in China. Zheng Lipeng said: "If we really want to have core competitiveness, we must achieve comprehensive control from hardware manufacturing to software design."

In Taizhou, the dual clutch module and hydraulic module will be produced independently, which means that all the core components of the automatic gearbox can be controlled by the hive. At the same time, the control software of automatic gearbox is also owned by Honeycomb, and the engine control software will also be independently developed by the end of next year.

It is worth noting that turbocharger, transfer case, hydrogen fuel cell air compressor, 70Mpa hydrogen storage bottle, valve body and honeycomb are also laid out, and some production lines are under construction. These are areas that were once monopolized by foreign companies in the past.

"When we have the ability to produce key components such as dual clutch modules and hydraulic modules, it does not mean that we will weaken cooperation with companies such as Borgwarner and Schaeffler, which are still the most important partners of the hive." Zheng Lipeng emphasized that the ability of self-production can convince the partners that the hive has mastered many patents in these key areas.

"Gun 2020 2.0T Travel Edition"

In Zheng Lipeng’s view, "when others get your new technology and design, they are mostly skeptical, but if we can verify and produce, it will not be like this." It is reported that according to the feedback from users of Great Wall H9 and Gun, it is hoped that the next generation of transfer gears can shift gears dynamically and their performance will be further improved. To this end, the Great Wall has put forward a brand-new design and is talking with suppliers about how to produce it.

All kinds of new ideas are based on the demand of product differentiation. Looking back many years ago, China enterprises such as Great Wall were still very weak, and they had no right to speak when talking about cooperation with top suppliers in the world. It was good that the other side was willing to cooperate and provide products. Now, when the procurement demand of the Great Wall is large enough and the market is rich enough, a new concept of positive research and development will be needed to build a competitive advantage.

"We don’t have to do everything ourselves. The actual application is external suppliers plus some self-production. The purpose of self-production of key components is to master core technical capabilities and cultivate local supply chains. " Zheng Lipeng said, "We have basically achieved 100% localization of all products."

It is expected that the honeycomb enterprises will start to support local enterprises with their own core technologies.

In fact, Honeycomb Yichuang has been looking for opportunities for foreign breakthroughs since it confirmed its independence from the Great Wall in 2018. In August 2019, BAIC, Great Wall and SDIC China Merchants (the management company of SDIC Innovation and the second largest shareholder of Honeycomb Energy) signed a strategic cooperation agreement. Since then, BAIC and Honeycomb Yichuang have become closer and closer. In May this year, the new Beijing BJ40 was launched with HY4C20B 2.0T gasoline engine produced by Honeycomb Yichuang. This is the cooperation between two China brand car companies, BAIC and Great Wall, and it is also the result of Honeycomb’s active external support.

"Beijing BJ40 2020 2.0T automatic four-wheel drive urban hunter edition"

Before the end of next year, in addition to BAIC, Honeycomb Yichuang will also add four engine customers and two gearbox customers, and the development work is currently underway. In addition, the new customer cooperation information of motors and batteries will be released one after another, and the hybrid special transmission DHT will also support some new forces to build cars in the future.

■ cut in from mixing to create an ecological circle

Not long ago, the "Technology Roadmap 2.0 for Energy-saving and New Energy Vehicles" just officially released has been very clear. It is planned that by 2035, the proportion of energy-saving vehicles and new energy vehicles in China will each account for about 50%. This means that the policy orientation confirms the important strategic position of energy-saving hybrid vehicles.

At present, the choice of hybrid technology route is not the same in the major automobile markets around the world. In China, the application of P2 and DHT architecture is more prominent. From the perspective of consumer demand, in addition to energy saving and consumption reduction, different consumer groups show diversity in cost performance, power and extreme demand, and the research and development innovation of hybrid technology requires multiple design concepts.

"Honeycomb Easy-to-Create Hybrid System Solution"

According to the data, Honeycomb Yichuang has created a hybrid product design concept of power system called "X in One". Where "X" stands for diversified product R&D platform, "in" stands for diversified integration of power system, and "One" stands for flexible product service oriented to customer demand.

Zheng Lipeng said that such a platform combination can meet the needs of different user groups.

At present, Honeycomb has built 2.0T and 3.0T hybrid engines. Matching 9HDCT and DHT hybrid transmission in transverse structure, matching with 1-speed or 2-speed eAD electric drive axle, can match the honeycomb energy lithium-ion battery (PHEV); Under the vertical structure, it is matched with the 9HAT and DHT hybrid special transmission, and the first gear TOD2 is a high-performance transfer gear for TOD, which can match the lithium ion battery (PHEV).

In the longer term, platformization is just the beginning. In the future, based on the platform and resource advantages within the Great Wall Holding System, Honeycomb Yichuang will strive to build a full-spectrum automotive powertrain technology ecology covering traditional-hybrid-pure electric-hydrogen fuel power. Honeycomb Yichuang will cooperate with Honeycomb Energy and Unprovoked Energy to build a full-spectrum business ecosystem of future automobile power system around the future automobile power system.

By 2025, Honeycomb will achieve an engine capacity of 1.95 million units, a gearbox capacity of 2 million units, an electric motor drive capacity of 550,000 units and a power battery capacity of 100GWh h..

Editor’s summary:

In recent years, it is a trend that the excellent parts enterprises cultivated by the automobile factory are gradually independent, but it is not easy to really get rid of the backer to achieve external supply. Honeycomb Easy Creation, Honeycomb Energy, Unprotected Energy, and three other independent parts enterprises cultivated by the Great Wall are all worthy of in-depth study.

The breakthrough of honeycomb enterprises began with engines and automatic gearboxes, and strengthened the route of hybrid, pure electric and hydrogen energy. Nowadays, Honeycomb is easy to create, including Honeycomb Energy and Unprotected Energy. The total number of employees in the world has reached 18,000. Team management may be a relatively difficult problem for Honeycomb. In fact, Wei Jianjun, the chairman of Great Wall Motor, has been promoting the reform, and Honeycomb is also following up the establishment of combat units and mechanisms, and implementing the concept of coordinated operations. In Zheng Lipeng’s eyes, the Great Wall provides a very clean platform for the right people to do the right things, without any professional background. As long as you have the ability and can respond quickly, you will have a chance to rise. (Text/car home Liu Honglong)