See how a machine tool can refine the "heavy weapon of the country"

In Guangling Economic Development Zone, the workshop of hot die forging intelligent equipment project is under construction. The project was built by Yangli Group with an investment of 850 million yuan. After completion, it can produce 10 intelligent production lines of large servo multi-position presses and 50 sets of intelligent equipment for hot die forging every year.

Industrial machine tools (machine tools) are the basis of manufacturing industry, and are called "the heavy equipment of the country". For a long time, the domestic high-end CNC machine tool field is highly dependent on imports. Yangli Group invested in the construction of a complete set of intelligent equipment for hot die forging, and advanced into the field of high-end industrial machine tools, which is a vivid case of the breakthrough in the industrial chain of industrial machine tools and robots in our city. The data shows that there are 65 industrial enterprises in the industrial chain of industrial mother machines and robots in the city, which have formed the characteristics and advantages of metal forming machine tools, high-end single (set) equipment to drive the development of complete production lines and integrated application of industrial robots.

The ambition of "individual champion"

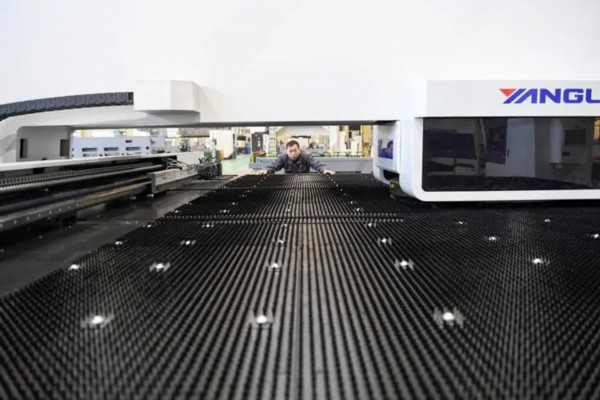

Yangli Group is a single champion enterprise in the mechanical press manufacturing industry, and is committed to the research, development, manufacture and sales of forging equipment. Its main products include mechanical presses, hot die forging presses, CNC turret punches and complete sets of equipment, which are widely used in aerospace, automobiles, home appliances and other fields at home and abroad.

Hot die forging equipment is mainly suitable for precision die forging under mass production conditions. "After years of technical accumulation and research, we have successfully developed an intelligent and efficient hot die forging press and an intelligent and efficient precision forging flexible production line, and the key indicators such as production rhythm have reached the international advanced level." Zhang Jun, vice president of Yangli Group, introduced that the products have been demonstrated and applied by well-known enterprises in forging, auto parts and other industries. "With hot die forging, warm forging, cold forging, electric screw main engine and automatic production line as the main products, we are confident to become a first-class heavy manufacturing equipment production base at home and abroad." Zhang Jun introduced that it is estimated that after the completion of the intelligent hot die forging equipment project, the annual sales of new invoices will be about 1 billion yuan, and the new tax payment will be about 70 million yuan. In recent years, Yangli Group has been focusing on intelligent manufacturing, focusing on high-end forging equipment and automatic production line technology research and development. At present, the domestic market share is leading in this field.

In the subdivision of home appliance sheet metal forming equipment, the product technology of flexible intelligent production line for home appliance precision sheet metal forming developed by Yangli Group has reached the domestic leading and international advanced level. The product customers include Haier, Midea, TCL and other major domestic home appliance enterprises, and are exported to South America, Russia and other countries and regions, leading the domestic market share industry. In addition, in the subdivision of forming equipment for passenger car panels, the overall technology of intelligent flexible stamping production line for passenger car panels developed by Yangli Group is leading in China, and its customers include domestic and foreign well-known automobile manufacturers and first-class suppliers, and its domestic market share is among the best.

Breakthrough of "Yangzhou Legion"

Industrial machine tool is one of the advantageous industries in our city. Four of the top 10 domestic metal forming machine tool manufacturers are located in Yangzhou, namely Yangli Group, Yawei Co., Ltd., Yangzhou Forging and Jinfangyuan. Hanjiang CNC forming machine tool industrial cluster was selected as the national small and medium-sized enterprise characteristic industrial cluster in 2023, which is the only one in the middle and northern Jiangsu.

In recent years, the "Yangzhou Corps", an industrial chain of industrial machine tools and robots, has continuously increased its scientific and technological research and development efforts and conquered a number of key new technologies. The project technology of "Key Technologies and Complete Equipment for Intelligent Sheet Metal Processing" developed by Yawei Co., Ltd. is leading in China. A number of key core technical research projects, such as automatic hot die forging complete sets of equipment for Yangzhou Forging and Yangli Group’s large brake clutch with low inertia, have filled the gaps in China. Guiyu Aviation has developed and manufactured a variety of high-precision machine tools to meet the domestic market demand.

In addition, Yawei Co., Ltd. and Yangli Group have built a national-level industrial Internet logo analysis secondary node to provide enabling services to the industry. Yawei Zhiyun of Yawei Co., Ltd. was approved as the national industrial Internet demonstration platform, providing "hard+soft+cloud" integrated intelligent manufacturing services for more than 1,000 downstream SMEs. With the help of industrial Internet platform, Jiangsu Yizhong CNC machine tool developed a remote customer service support system to provide remote monitoring, fault diagnosis, guidance and maintenance of machine tools. In terms of market expansion, enterprises in the industrial machine tool industry in our city have laid out new fields such as new energy vehicles, photovoltaics and 5G. Yawei Co., Ltd. won the order of 5000 tons of heavy-duty bending machine and made a new breakthrough in the largest tonnage order of domestic CNC bending machine; Yang Forging deepened cooperation with the OEM of new energy automobile enterprises and delivered a complete set of automatic production line & HELIP; … A number of projects under construction are accelerating the strengthening of the industrial chain, supplementing the chain and extending the chain. According to statistics, in the industrial chain of industrial machine tools and robots, there are 25 major projects under construction in the city this year, with a total investment of more than 3 billion yuan. Among them, Yangzhou Dolphin Star Intelligent Technology Co., Ltd. invested 500 million yuan to build an annual output of 6,000 Dolphin Star intelligent handling robots, and Yawei Co., Ltd. invested 680 million yuan to build servo presses and automatic stamping line production projects.

Shaping new competitive advantages

Industrial mother machine is a typical general equipment with obvious periodicity. With the rapid growth of new energy vehicles, photovoltaic, wind power, 5G and other emerging industries, the application fields of industrial mother machines are increasing. Industry experts predict that the industry will develop rapidly with a compound annual growth rate of over 10% in the future.

Our city has made clear the development goal of industrial mother machine and robot industry chain this year: the output value of enterprises is 11 billion yuan; Breakthroughs have been made in the development of major equipment, and about five iconic high-end industrial mother machine products have been developed; In key areas such as new energy vehicles, aerospace and electronic information, we will create 10 typical innovative application scenarios … …

Tang Lan, director of the Mechanical Equipment Division of the Municipal Bureau of Industry and Information Technology, said that in order to achieve the above objectives, this year, we will speed up the cultivation and development of new quality productivity through six aspects, and create new advantages for the high-quality development of the industrial chain. Organize high-end product technology research. Relying on the backbone enterprises of Yawei, Yangli and other industries, the "mainframe+components+technology+application" research consortium and Industry-University-Research Innovation Alliance will be established. Actively strive for the support of major national industrial machine tools projects, provincial key core technology research and scientific and technological achievements transformation projects. Accelerate the construction of major projects. Promote the implementation of Jinfangyuan expansion project and expand the production scale. Promote the construction of 25 major projects to ensure that the projects reach production and efficiency on time. Promote special investment promotion in industrial chain. Draw up the investment map of industrial chain around key materials, parts and systems, complete machine manufacturing and other links, carry out professional investment in supporting fields, attract supporting enterprises to invest, and strive to make breakthroughs in local supporting of key core parts. Strengthen the construction of public platforms. Explore the reconstruction of Jiangsu (Yangzhou) CNC Machine Tool Research Institute, improve the "1+N" (Yangzhou+several well-known universities) cooperation mechanism, and accelerate the research and development of common technologies for industrial mother machines and robots. Yangzhou Branch of the General Institute of Propulsion Machinery has built intelligent and flexible production demonstration projects around the fields of forging and other materials forming, high-precision CNC machining to reduce materials and laser welding to increase materials. Vigorously develop service-oriented manufacturing. Promote leading enterprises such as Aviles and Yangli, and focus on new fields such as new energy vehicles, electronic information and heavy-duty equipment.We will develop a number of industry-leading new intelligent manufacturing equipment, and carry out services such as integrated design of manufacturing engineering and intelligent operation and maintenance of equipment. In-depth development of linked service activities. The first Summit Forum on Innovation and Development of Forging Industry and the Expert Summit of China Forging Association will be held to promote the collaborative innovation of upstream and downstream enterprises in the industrial chain. Strengthen the docking cooperation with the national industrial machine tool industry investment fund to realize the development of national fund-enabled industries. Start the activities of "observing and observing the benchmark", organize key enterprises to go out to visit benchmark enterprises, and plan to carry out more than 20 service activities throughout the year.

Reporter’s notes

Valuable climbing "high" and pursuing "new"

In the enterprise interview, I deeply felt the value of the development of industrial mother machine and robot industry chain: constantly climbing to the high end. Yangli Group built a complete set of intelligent equipment for hot die forging to expand its production capacity, and Guiyu Airlines developed high-precision machine tools to meet the domestic market demand; Yawei Co., Ltd. and Yangli Group built the second-level node of national industrial Internet logo analysis, and completed the gorgeous transformation from manufacturer to service provider … … Yangzhou enterprises have laid out new fields such as new energy vehicles, photovoltaics and 5G, developed new markets and expanded new space for industrial chain development. Relying on innovation, industrial machine tools and robot industry chain enterprises are getting rid of the traditional development mode and accelerating the cultivation and development of new quality productivity. Enterprises are the main body in developing new quality productive forces. Twenty-five projects under construction are lengthening and enriching the industrial chain, reflecting that Yangzhou’s excellent business environment is becoming a fertile soil for incubating new quality productivity. This year, our city will carry out six key tasks, speed up the breakthrough of the industrial chain, and create new advantages for the high-quality development of the industrial chain. It is reasonable to believe that the development of industrial machinery and robot industrial chain will usher in a better tomorrow.

Expert comments

Continue to make efforts to upgrade files.

□ Fu Dongli, Chief Expert of Yangzhou Industrial Machine Tool and Robot Industry Chain, Dean of Jiangsu Mechanical Design and Research Institute and Professor-level Senior Engineer

Industrial machine tool is the "machine tool", which is the foundation of manufacturing industry and has an important supporting position in the national economy; Robot is an important symbol of scientific and technological innovation and high-end manufacturing level, and it is also the new blue ocean of manufacturing industry in the future.

Yangzhou industrial machine tool industry has a long history and a solid foundation, forming the characteristics and advantages of taking metal forming machine tools as the main part, cutting machine tools as the supplement, and high-end single (set) equipment to drive the development of complete production lines. Especially in the field of metal forming machine tools, it is unique. Four of the top 10 domestic metal forming machine tool manufacturers are in Yangzhou. However, compared with advanced regions, there are still problems such as small overall scale and insufficient industrial support, which need to be continuously exerted to promote the upgrading of the industrial chain.

I have three suggestions: First, promote the backbone enterprises to become bigger and stronger, aim at expanding the industrial scale, and concentrate superior resources to cultivate key enterprises. The second is to consolidate the supply chain foundation of the industrial chain and promote the transformation and upgrading of traditional parts supporting enterprises to intelligent greening; Carry out professional investment promotion in the field of machine tool supporting, and strive to make a breakthrough in the local supporting of key core components. The third is to strengthen the platform construction of integration of production and education, guide key enterprises to strengthen cooperation with institutions of higher learning, and promote the construction of integration of production and education.